A guide to nitrogen management for rice in the tropics

Jan 12, 2017There’s a building thirst for knowledge from growers about optimal nitrogen management in upland rice production in this emerging industry.

Download this article

While it is early days in terms of research outcomes, growers can rely on the principles of rice crop development, nutrient requirements and an understanding of nitrogen loss mechanisms to make informed and appropriate management decisions.

What we know so far is that nitrogen in rice is very much a balancing act.

Too little nitrogen reduces yield potential. Too much nitrogen leads to excessive growth, making the crop prone to lodging and increasing the risk of nitrogen losses.

Let’s start by looking at the ways nitrogen can be lost from the system.

Understanding nitrogen losses

There are three ways nitrogen can be permanently lost from a rice crop. These are:

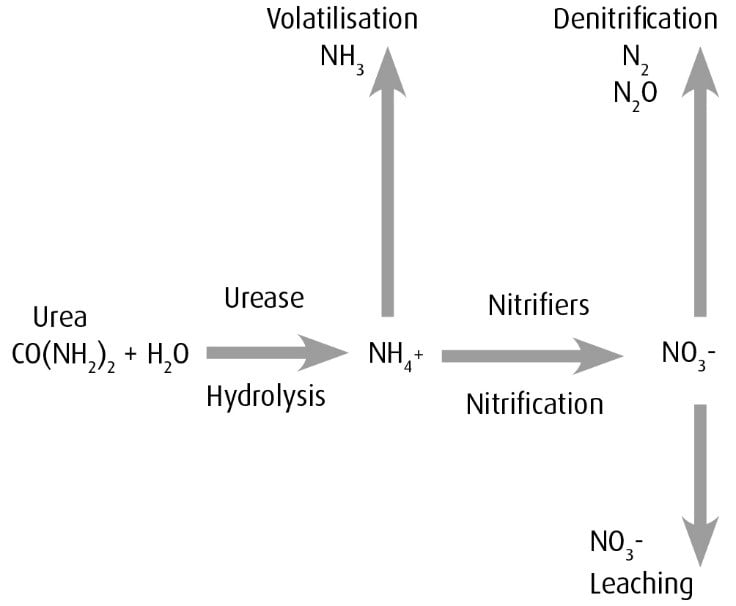

- Leaching – the movement of nitrate nitrogen below the root zone

- Denitrification – the loss of gaseous nitrous oxide or nitrogen gas to the atmosphere

- Volatilisation – the loss of gaseous ammonia to the atmosphere.

Firstly, the risk of leaching losses is greatest on sandier soils, or any soil with a cation exchange capacity of less than four, after high amounts of rainfall or irrigation.

The nitrate nitrogen moves with the water through the soil and beyond the root zone so it can’t be used by the crop.

Secondly, denitrification is also a loss affecting nitrate nitrogen. Under limited oxygen conditions (i.e. saturated or waterlogged soils), soil microbes can use otherwise plant available nitrate as an oxygen source resulting in nitrous oxide and nitrogen gas being released and lost to the atmosphere.

In northern rice systems, where tropical rain events combine with warm soils, denitrification losses can be very significant. Under conditions like this, it is not unusual for 30% of nitrate nitrogen to be lost (Chen et al 2008)1.

Thirdly, volatilisation losses can occur when urea is surface applied and not incorporated into the soil by tillage, irrigation or rainfall.

This process occurs when urea reacts with water in the presence of a naturally occurring enzyme and is converted to ammonia, a gas which is then lost from the soil and the crop.

Volatilisation losses are driven by an alkaline pH – the higher the pH in the reaction zone around a fertiliser granule, the greater the potential for volatilisation. This is the issue with urea when it is surface applied, because once the urea starts to dissolve, the localised pH around the granule increases significantly. High pH is the mechanism that creates ammonia gas.

How urea becomes plant available and its associated potential loss mechanisms

So with an understanding of nitrogen loss pathways, what can be done to minimise these?

Apply urea or urea blends under the ground. This will virtually eliminate volatilisation losses. Growers can also use irrigation within a day or two of urea broadcast applications to move the fertiliser into the soil to protect against volatilisation.

If these steps cannot be taken, consider a nitrogen fertiliser source which is not based on urea, such as ®Cal-Gran or Gran-Am®. Also consider using the enhanced efficiency fertiliser, Green Urea NVTM, which is a urea treated with a urease inhibitor to minimise volatilisation losses for up to 14 days.

This takes care of volatilisation losses. Minimising the risk of denitrification losses is a little more complex.

Ideally, growers should avoid having high nitrate nitrogen levels in the soil when waterlogging events are likely and particularly under warm conditions.

This is not always possible in tropical rice growing systems.

Also, the high rainfall events that are likely in the wet season can result in leaching losses.

The answer – growers can use ENTEC® Urea and fertiliser blends based on ENTEC Urea to help protect against leaching and denitrification losses.

This enhanced efficiency fertiliser stabilises the applied nitrogen in the ammonium form for a period of time. This minimises the levels of nitrate nitrogen in the soil without denying crops access to nitrogen. Rice can accommodate the uptake of nitrogen in both the ammonium and nitrate forms and actually has a strong preference for ammonium nitrogen.

ENTEC is a great option for rice growers looking to improve nitrogen uptake, reduce loss potentials and achieve better results under typical wet season conditions.

Splitting nitrogen applications is another important way for growers to manage production and loss risks.

Most growers aim to supply a significant proportion of the estimated crop nitrogen requirement before planting and then top up as required early in the season and/or at panicle initiation.

When battling the weather, no approach is ever guaranteed. However, here is a simple framework for nitrogen management to use as a template in aerobic rice crops.

Pre-plant fertiliser choices

Applying a significant amount of the nitrogen fertiliser before planting helps ensure sufficient vegetative growth and nitrogen uptake in the early stages of growth to set the crop up for a high yield.

Ensure the nitrogen is placed deep enough in the soil so that it doesn’t affect the germinating seed and inhibit plant establishment. Drill the fertiliser at least 5 cm below and also to the side of the intended seed line.

Soil testing and recent crop history will help determine the amount of potassium fertiliser to apply and which form of potassium fertiliser will be most appropriate.

Urea and urea blends are appropriate for pre-plant applications, provided the fertilisers are applied into the soil, so that volatilisation losses do not occur.

However, to also limit leaching and denitrification losses, choose ENTEC Urea or an ENTEC Urea blend, applied into the soil.

ENTEC stabilises the nitrogen in the soil so that it stays in the ammonium form for longer. This mechanism minimises the losses while not withholding nitrogen from the crop because rice plants will take up nitrogen in the ammonium form.

By reducing losses and stabilising the nitrogen in the soil, ENTEC Urea could extend the period of nitrogen availability to the crop, potentially reducing the need for one or more in-crop nitrogen applications, depending on growing conditions.

The amount of nitrogen fertiliser required pre-plant will depend on the previous paddock history, soil nitrogen levels and the yield potential. For example, rice following sugar cane will require more nitrogen than rice following a legume crop.

Planting fertiliser

Rice has a significant zinc requirement and banding phosphorus and zinc at sowing can improve rice growth and yields.

Granulock® Z delivers a carefully balanced formulation of starter nutrients to promote vigorous establishment. It contains 11% nitrogen, 21.8% phosphorus, 4% sulphur and 1% zinc in every fertiliser granule.

Improved zinc nutrition is important, particularly on alkaline soils because the availability of zinc to plants reduces as pH increases.

Granulock blends are also available to provide tailored nutrition to your crop.

Granulock Z can be applied with the seed if the rate is within seed safety guidelines. This gives the emerging seed direct access to soluble phosphorus for successful early crop establishment.

Fertilisers at mid-tiller and panicle initiation

Additional nitrogen applications are likely to be required in-crop to help keep the rice crop growing actively and support high yields.

This is the time to fine tune the nitrogen supply to match crop requirements and set yield potential.

Growers may choose to make one or two nitrogen applications over these crop stages, depending on their preferences and influenced by block trafficability.

There are a range of effective options:

- If it is possible to schedule irrigation within a day or two of the application, growers can broadcast ENTEC Urea on to the crop.

- Alternatively, Green Urea NV, Cal-Gran or Gran-Am can be broadcast if rainfall or irrigation is not expected within three to four days or longer. Green Urea NV will provide up to 14 days’ protection against volatilisation. Cal-Gran or Gran-Am minimise volatilisation for even longer.

- EASY N® or ENTEC EASY N can be water run with irrigation. EASY N is a liquid nitrogen fertiliser containing 42.5% nitrogen (w/v) in the urea, ammonium and nitrate forms. With ENTEC added to EASY N, both leaching and denitrification loss potentials are reduced.

Finally, ensure that if any nitrogen is to be surface applied, the banks are pushed up at the end of the rows to contain the tail water within the block or if irrigating and ideally choose a site with a recycle pit to minimise nitrogen run-off losses.

The right fertiliser strategy for your rice crop will depend on the specifics of your situation – the paddock history, the surface and subsoil soil test results, the growing system, weather, irrigation availability and your target yield.

As there is no substitute for professional agronomic advice, always seek more information or talk to your local Fertcare accredited advisor.

Also, feel free to contact me on 0428 111 471 or rob.dwyer@incitecpivot.com.au.

1 Chen D, Suter H, Islam A, Edis R, Freney JR, Walker CN (2008), Prospects of improving efficiency of fertiliser nitrogen in Australian agriculture: a review of enhanced efficiency fertilisers, Australian Journal of Soil Research. 289-301.