Easy N for late N applications in cereals

Aug 15, 2022Nitrogen drives yield in winter cropping systems. However, environmental conditions in the later stages of crop development make fertiliser applications difficult. While available soil-moisture at topdressing may be known, future rainfall events, frosts, heat shocks, and the length of the grain-fill period, are all unknown and can have an impact on both yield and protein.

Click here to download this article

LEE MENHENETT

TECHNICAL AGRONOMIST

At most crop growth stages the type of nitrogen fertiliser does not make a significant difference to fertiliser recovery. However, later in the crop’s development, EASY N has shown to be more effective than Urea. This could be because of some leaf uptake, lower volatilisation potential (lower solution pH, ammonium, and nitrate forms of nitrogen) and nitrate-nitrogen that is rapidly taken up via mass flow with moisture.

GROWTH STAGES

As the crop develops, nitrogen accumulates in the plant (Figure 1). During the vegetative growth stages, nitrogen demand is relatively low. However, once the crop moves into their productive growth stage, nitrogen demand increases significantly. Ensuring the crop has access to adequate nitrogen at the right growth stages, when the key yield components are set, is vital to achieving optimum yield.

The first component is tiller number. Plant stress during and after tillering can decrease tiller set or cause tiller death thereby reducing the number of spikes (or heads) per plant.

Grain number is set from mid-tillering to mid-flowering, with the final number determined at flowering. Ear initiation commences when the plant has four leaves and concludes at the end of tillering. This is also when the number of spikelets per tiller is set.

Figure 1. Nitrogen uptake in medium yielding (5 t/ha) wheat crop and influences on grain yield and protein. Source: Incitec Pivot Fertilisers 2003.

From first node to booting each of these spikelet positions develops several florets. Around flag leaf emergence to booting the ear grows rapidly, and egg and pollen cells are initiated. At the conclusion of booting, the maximum floret number has been set.

After booting, nitrogen has minimal influence on yield. Therefore, ensuring adequate nitrogen supply up to this point is critical in not only setting yield but also protecting yield potential. Leaving most of the nitrogen applications closer to booting can be risky. Adequate soil moisture, effective rainfall and surface root activity are required.

Grain weight is determined during grain fill. Starch is deposited in the grain from photosynthesis of plant parts including leaves, stem, and head. The longer and cooler the season finish, the greater starch deposition can occur, culminating in larger and heavier grains.

Grain protein is derived from stored leaf nitrogen. Low leaf tissue nitrogen levels at flowering can lead to low protein values, although grain size determined by the length of the season can play a large role in the concentration of protein with the grain.

With increasing dry matter accumulation during reproductive growth stages, longer days and warmer temperatures, plant evapotranspiration rates increase to greater than 5 mm/day. A 25 mm rainfall event captured by surface wheat roots will supply the plant moisture for only five days, with the plant needing to use roots deeper in the soil profile to recover moisture. This is one of the reasons later nitrogen applications can be less efficient. Several rainfall events would be required to maintain moisture in the top of the soil profile, firstly to move the nitrogen into the soil, and secondly to encourage prolonged surface root activity to recover the applied nitrogen. As the crop develops past anthesis, roots begin to senesce, further decreasing the plants nutrient and moisture foraging capability.

APPLYING EASY N

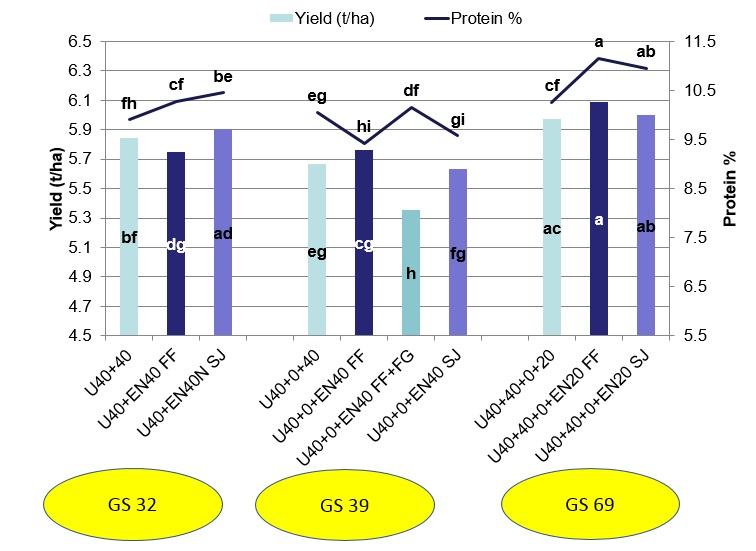

Data from a wheat trial at Dookie in 2013 (Figure 2) showed the influence on wheat yield and protein from varying nitrogen rates, split timings, product choices and application methods (broadcast, SJ streaming nozzles, FF flat fan nozzles). GS32 applications saw no yield differences (Figure 2.), however EASY N applied with streaming nozzles gave a significant protein increase over Urea.

GS39 applications provided no significant differences in yield, except the EASY N FF+FG treatment (Prosaro fungicide, wetter and EASY N) which was significantly less than the other treatments. This yield decrease can be attributed to large degree of leaf burn (see Photograph 1).

EASY N flat-fan applications at 94l/ha (40kgN/ha) did not decrease yield compared to Urea and EASY N streaming nozzle applications. Protein levels were significantly higher in the Urea and EASY N FF + FG treatments.

At GS69, another 20 kg N/ha was applied that did not increase yield of any treatments. However, both EASY N treatments (FF and SJ) significantly increased grain protein.

TARGETING PROTEIN

As wheat crops develop and yield potential increases, opportunities remain to apply nitrogen – up to booting – to match yield increases. Nitrogen applications around flowering can positively influence grain protein levels. These applications need to be considered in conjunction with price differences in protein spreads, efficiency of nitrogen applications, and confidence in moving up to the next protein grade.

The efficiency of nitrogen uptake will decrease with later applications. Rainfall events will assist in nitrogen recovery.

As the seasons progress, it can be demonstrated that EASY N is the product of choice.

Figure 2. Comparing Urea and EASY N and different growth stages. Application rates are 40 kg N/ha (94 l/ha EASY N & 87 kg/ha Urea) and 20 kg N/ha (47 l/ha EASY N and 43.5 k/ha Urea). Source: Incitec Pivot Fertiliser 2013.

Photograph 1. EASY N + Prosaro fungicide and wetter applied at GS39 with flat-fan nozzles. IPF Trial Site – Dookie 2013.

FURTHER INFORMATION

For more information or advice about using Easy N for late season topdressing feel free to contact me on 0412 565 176 or lee.menhenett@incitecpivot.com.au.

DISCLAIMER

This is a guide only, which we hope you find useful as a general tool. While Incitec Pivot Fertilisers has taken all reasonable care in the preparation of this guide, it should not be relied on as a substitute for tailored professional advice and Incitec Pivot Fertilisers accepts no liability in connection with this guide.

Incitec Pivot Fertilisers manufactures and sources fertilisers from other suppliers. The fertiliser supply chain extends beyond the company’s direct control, both overseas and within Australia. Incitec Pivot Fertilisers hereby expressly disclaims liability to any person, property or thing in respect of any of the consequences of anything done or omitted to be done by any person in reliance, whether wholly or in part, upon the whole or any part of the contents of this article.